What Are Non Woven Fabrics Used For? Key Examples & Features

In an era defined by performance, precision, and sustainability, materials are no longer just passive components. They are enablers of innovation. Among them, non-woven fabrics have quietly emerged as one of the most transformative forces in modern manufacturing.

Explore Recent Blogs

Spunlace Nonwoven Fabrics: Explore Characteristics and Benefits

In a world where hygiene, safety, and softness intersect, material science has a quiet hero, spunlac

Read More

PentaTech™ by Elixrr Nonwovens: Pioneering the Future of High-Performance and Sustainable Nonwovens

Innovation in nonwoven materials isn’t optional anymore. It’s what drives progress. As industrie

Read More

Is Non-Woven Fabric Biodegradable? Exploring the Eco-Friendliness of Non-Wovens

Every business is searching for environmentally appropriate substitutes as the globe moves towards s

Read More

What Are Non Woven Fabrics Used For? Key Examples & Features

In an era defined by performance, precision, and sustainability, materials are no longer just passiv

Read More

Weave Your Success with Our Revolutionary Fabrics

Power your business with Elixrr's cutting-edge nonwoven fabric solutions. Eco-friendly, customizable, and engineered for excellence—because innovation starts with the right foundation.

In an era defined by performance, precision, and sustainability, materials are no longer just passive components. They are enablers of innovation. Among them, non-woven fabrics have quietly emerged as one of the most transformative forces in modern manufacturing. Often overlooked in favour of flashier technologies, these fabrics are everywhere: in the air we breathe, the cars we drive, the food we eat, and the care we receive.

Unlike traditional woven or knitted textiles, non-wovens are not defined by yarns and looms. Instead, they are engineered. Structured at the fibre level to deliver highly specific characteristics such as breathability, strength, absorbency, or barrier protection. This ability to tailor the fabric’s function at its very core is what makes non-wovens so unique, and so powerful.

But their story is not just technical. It is also a story of how industries are rethinking scale, sustainability, and design. From a surgical mask that balances filtration with comfort to a crop cover that reduces water usage while boosting yield, non-woven fabric is not a single material. It is a toolkit.

In this blog, we take a closer look at the uses of non woven fabric, explore compelling non woven fabric examples across industries, and highlight the key characteristics that make them indispensable. Along the way, we will also share how Elixrr is setting new standards for what non-wovens can achieve and why it matters more now than ever.

What Are Non-Woven Fabrics?

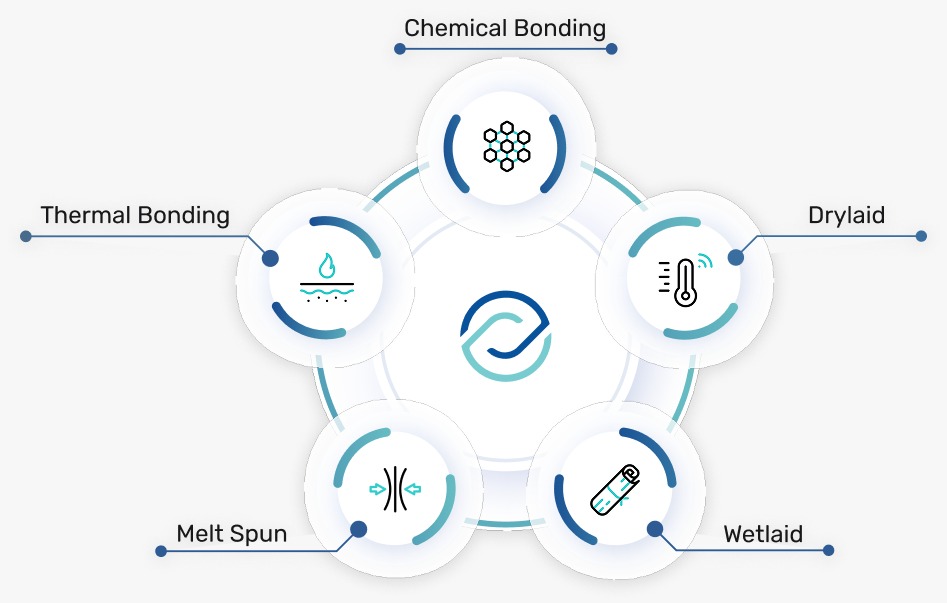

Non-woven fabrics are made by bonding fibres together mechanically, thermally, or chemically, rather than weaving or knitting. This results in a fabric that can be tailored in thickness, texture, durability, and absorption, all without the constraints of traditional textile manufacturing.

At Elixrr, we produce spunbond non-woven fabrics using proprietary Pentatech™ technology, enabling unmatched consistency, strength, and softness across every roll.

A Brief History of Non-Wovens

While non-woven fabrics are often seen as a modern innovation, their origins trace back further than many realise. The earliest instances of non-woven-like materials date back centuries. Felt, for example, is one of the oldest known textile structures, created by matting natural fibres using heat, moisture, and pressure.

The commercial journey of non-wovens began in the mid-20th century. In the 1940s, with the rise of synthetic polymers like polyester and polypropylene, industries started experimenting with fibre bonding methods that bypassed the loom entirely. These processes promised faster production, lower costs, and new material properties. The results quickly proved transformative.

By the 1960s, non-wovens had gained a foothold in hygiene and medical applications, offering disposable solutions that were cleaner, safer, and more affordable. As manufacturing technologies advanced, so did the potential of non-woven fabrics. Thermobonding, spunbonding, and meltblown techniques enabled high-volume production with increasingly specialised performance characteristics.

Today, the non-wovens industry is a multi-billion-dollar global sector, with applications spanning healthcare, automotive, agriculture, construction, filtration, and beyond. What began as an alternative to traditional textiles has matured into a category of its own. It is defined by adaptability, technical precision, and sustainability.

Key Characteristics of Non-Woven Fabrics

Lightweight yet Durable

Engineered for high strength-to-weight ratio, non-wovens can outperform many woven alternatives where performance matters.

Breathable and Soft

Ideal for skin-contact applications like hygiene products, non-woven fabrics are gentle and breathable while maintaining structural integrity.

Highly Customisable

From UV resistance to hydrophobic coatings, non-woven fabrics can be modified for highly specific end-use requirements.

Eco-Conscious Options

Elixrr’s range includes recyclable, degradable, and FSC®-certified non-wovens, aligning with global sustainability standards.

Cost-Effective Manufacturing

With lower production times and energy use, non-wovens enable manufacturers to scale faster and smarter.

Common Non-Woven Fabric Uses

Non-woven fabrics power multiple industries through innovation, hygiene, and sustainability.

Hygiene and Medical

Used in diapers, sanitary napkins, surgical gowns, and face masks, non-wovens offer excellent barrier properties with soft touch and breathability.

Agriculture

As crop covers and seed blankets, non-wovens help regulate temperature, reduce weed growth, and improve moisture retention.

Packaging and Filtration

From reusable shopping bags to industrial-grade filters, non-wovens deliver strength, reusability, and custom functionality.

Automotive Interiors

Used in cabin insulation, headliners, and carpeting, non-wovens improve durability while reducing vehicle weight.

Construction and Geotextiles

As roof linings, insulation layers, or erosion control fabrics, non-wovens add value across infrastructure projects.

These are just a few non woven fabric examples, and the list continues to expand as technology evolves.

Why Elixrr Nonwovens?

At Elixrr, we go beyond manufacturing. We engineer purpose-built, high-performance non-woven fabrics that deliver measurable value across every sector.

Made in India, Built for the World

Our Gujarat-based plant, built on Industry 4.0 standards, produces over 18,000 tonnes annually with unmatched precision and scalability.

Sustainable by Design

From zero liquid discharge to FSC-certified raw materials, sustainability is not an add-on. It is our foundation.

Powered by Pentatech™

Our proprietary tech ensures exceptional strength, uniformity, and softness in every metre we produce.

Flexible, Fast, Future-Ready

Whether you're in healthcare or horticulture, our customisation capabilities and rapid delivery timelines ensure you’re always ahead of the curve.

Ready to Make a Difference with Elixrr?

Non-woven fabrics are no longer just supporting materials. They are central to innovation across industries. And when performance, precision, and sustainability matter, Elixrr delivers.

Explore our product range or connect with our team to discover how Elixrr’s advanced non-woven solutions can power your next breakthrough.

Frequently Asked Questions

Q1: What are the main uses of non woven fabric?

Non woven fabrics are widely used in hygiene products, medical supplies, agriculture, filtration, packaging, and construction. Their versatility and customisation make them ideal for both disposable and long-term applications.

Q2: Can you give some common non woven fabric examples?

Yes. Examples include surgical masks, baby diapers, crop covers, reusable shopping bags, automotive insulation, and industrial filters. Each is designed with specific performance properties in mind.

Q3: How are non woven fabrics different from woven fabrics?

Non woven fabrics are made by bonding fibres without weaving or knitting, allowing for faster production and more functional customisation. Woven fabrics, by contrast, are created by interlacing threads in a traditional textile pattern.

Q4: Are non woven fabrics environmentally friendly?

They can be. At Elixrr, we use FSC-certified raw materials, offer recyclable and degradable options, and operate with a zero-liquid discharge system to ensure sustainable production at scale.

Q5: Why choose Elixrr for non woven fabrics?

Elixrr combines precision technology, high-volume production, and eco-conscious materials to deliver non woven fabrics that meet the exacting needs of modern industries. With Pentatech™ technology and a state-of-the-art facility, we provide quality you can trust.